Petrochemical Facility

Summarize the project's program, features and achievements.

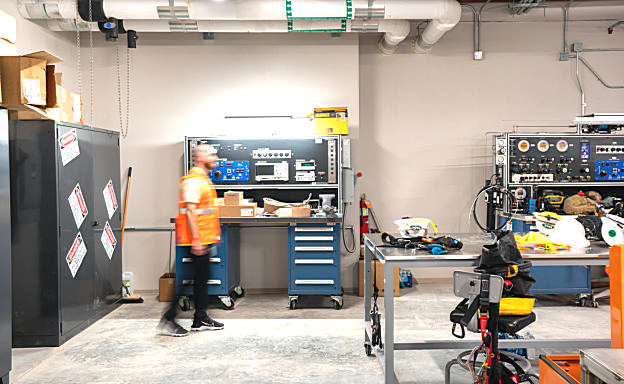

This state-of-the-art plastics manufacturing facility offers an efficient and effective design with an elevated experience. The 28-acre site in San Patricio County, Texas, includes an administration building, which is located in front of a secure fence on the property. Three buildings are located behind the fence: a warehouse complex, a laboratory building, and a firehouse. Starting with the arrival sequence, the guest journey is carefully curated. Welcoming landscaping and a scenic entryway lead to the administration building. This tilt-wall structure features an architectural statement piece that greets guests and leads them to the entry. The architecture of the building, including the canopies, materials, and certain design elements, reference the client's logo. The administrative building has three control rooms, an open workspace and huddle rooms, and a town hall gathering space. There is also an executive suite and boardroom, with a custom fabricated table made from one whole locally source Cypress tree, and even a prayer room to accommodate the needs of global executives and heads of state they will host. The warehouse is also tilt-wall construction, with a design that prizes functionally. It contains two high bays for equipment maintenance and repair with overhead cranes, an electronics lab, and storage with a high-tech automated retriever system, and office space. The laboratory building contains a lab for polyethylene material testing. Additionally, the plant can cover the immediate emergency response needs of the plant with the on-site firehouse with four bays.

What obstacles were overcome related to the schedule, budget, program, specification, site, etc. on this project?

A focus on the human experience, which often has a different meaning in an industrial plant setting, allowed the client to explore design solutions typically not seen with this project type. Meanwhile, efficient programming and cost-effective building techniques led to savings allowing them reinvest into the architecture of the buildings. Together, these factors create a facility that is budget friendly, yet still has the architectural character that appropriately represents the global stature of both companies. Gensler managed the entire design process through construction administration and commissioning, working with the client and design build partner to create design documents that implemented the original programmatic vision and budget provided. Throughout the detailed project building design process, the programmatic information continued to adapt to meet the site conditions. That information was then disseminated to the larger design and engineering team and implemented into the final construction documents. This required both lab planning and warehouse and hazardous material storage coordination, along with facility engineering design coordination. The campus required significant site utility and screening planning. Fire and domestic water were coordinated and connected to the plant loop; sanitary waste is pumped to the plant waste treatment facility. Electrical services were coordinated and tied into the new plant sub-station. Data was coordinated and connected to a TER (telecommunications equipment room) tower as well as connected and tied into the campus fiber system. All existing utility taps were required to be located via ground scanning and then hydro-excavated to avoid damage.

Communicate any engineering complexities or unique features of the panel design for this project.

Two of the three tilt-up buildings on the site (the administrative building and the laboratory) included complex panel geometry at the entries. At the admin building, two of the corners featured a combination of sloped panel edges, horizontal cantilevered panel ‘beams', and spandrel panels (supported on both columns and adjacent tilt panels). These panels not only has complex geometry, but were also some of the largest panels on the project, weighing as much as 170,000 lb. These panels were designed to support two elevated levels plus the roof, were included in the lateral system as shear walls, and were designed and detailed for the intricate canopy over the entry doors. The coordination included panel notches at the sloped side to hide the canopy tie-in, as well as 30-plus embed plates in the exterior face of the tilt panel to support the geometrically complex cantilevered canopy.

What is the potential for this project's impact on the community and/or environment?

Gensler's design looks beyond the immediate site and considers the broader context. Seeking to be good neighbors and stewards of nature, the client wanted their facility to blend into the community with park-like landscaping and access to nearby walking trails that connect to area lakes. An outdoor amenity and event area provides workers space to gather and connect. These amenities, coupled with an effective and efficient program, aim to help improve recruiting and the overall human experience.

Project Location

Gregory, TX 78387

United States

TILT-UP ACHIEVEMENT AWARD

The Tilt-Up Achievement Awards were established to honor projects that use site-cast tilt-up concrete to introduce new building types, advance industry technology and provide unique solutions to building programs. Winning entries illustrate the variety, beauty, and flexibility of tilt-up construction.

ACHIEVEMENT

2022

The world’s greatest tilt-up structures are featured by the TCA as Tilt-Up Achievement Award Winners. Learn more >

Project Images

Project Team (TCA Members)

- General Contractor:

- Concrete Contractor:

- Architect:

- Engineer:

- Pinnacle Structural Engineers

- Suppliers:

- Photographer(s):

- Grant Gay

Project Specifics

- Project Category:

- Production/Manufacturing

- Building Types:

- Administration Building

- Manufacturing Plant

- Finishes:

- Paint (Textured)

- Features:

- Voids

- Insulation:

- Post Applied (Interior)

- Environmental:

- LEED Certified

- Number of Floors:

- 3

- Number of Panels:

- 67 panels

- Tilt-Up Wall Area:

- 68,100 sq ft (6,326 sq m)

- Total Floor Area:

- 163,055 sq ft (15,148 sq m)

- Project Footprint:

- 73,855 sq ft (6,861 sq m)

- Tallest Panel:

- 54 ft 5 in (16.59 m)

- Widest Panel:

- 36 ft 8 in (11.18 m)

- Largest Panel:

- 1,995 sq ft (185.3 sq m)

- Heaviest Panel:

- 230,000 lbs (104,326 kg)

- Longest Spandrel:

- 32 ft 7 in (9.93 m)